Battle of the Techbots (PREVIEW Pt. 2 of 4): BeeF KaM vs. Flipping Awesome

A battle for Techbot supremacy is coming soon to the classrooms of Moraine Park. Here’s a preview of one of the first-round match-ups. Check out the bios and watch the videos below, and let us know who you think will win in the comments section!

PROJECT DETAILS:

Moraine Park’s Integrated Manufacturing Classes are required of students in the Mechanical Design, Process Engineering Technology, and Mechatronics programs. Students in these programs take the course together and work in cross-functional teams to complete a project. This year’s project was a Techbot competition. Four teams in the evening class and four teams in the day class are building remote-controlled robots that will compete against each other by battling in an 8ft x 12ft cage. Each team designed and built their Techbot from scratch. Limitations included a $250 budget and a 15-pound weight limit.

Preliminary rounds will take place on Wednesday, May 4 for the evening class, and Friday, May 6 for the morning class. The finals will take place on Wednesday, May 11.

If you want to get in on the fun and see what career opportunities await you, visit morainepark.edu/programs for all the details!

ROBOT NAME: BeeF KaM

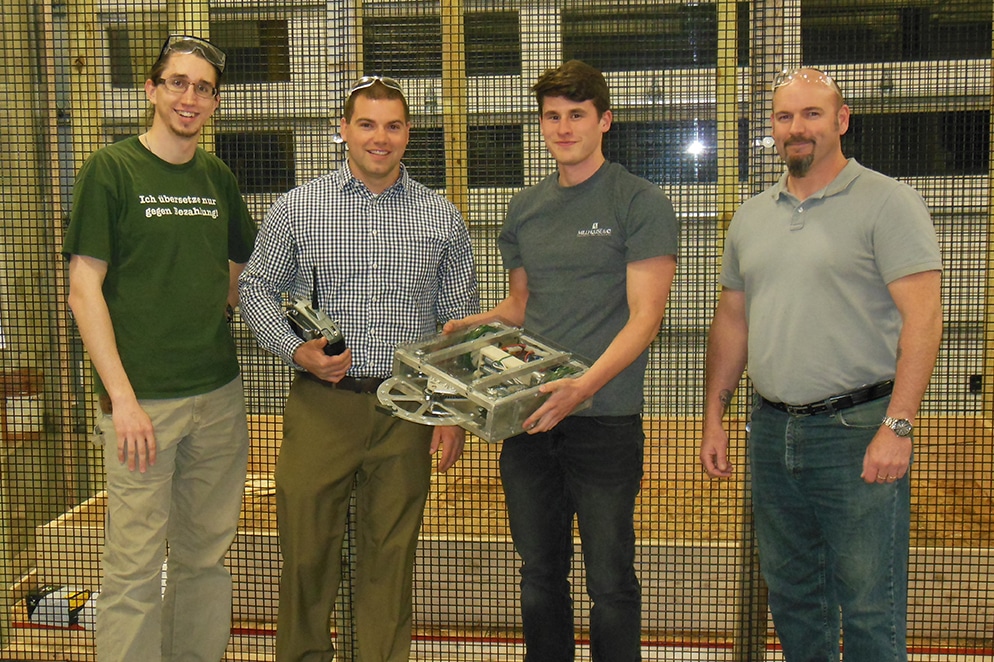

TEAM MEMBERS: Robert Bolwerk, Brian Fabus, Nathan Kelly, Wade Much

TEAM NAME: Team BFKM

CLASS: Evening

ROBOT FEATURES:

- BeeF KaM’s chassis was constructed of strong aluminum square tube that was welded together.

- He is driven and steered with two motorized wheels in the rear of the robot and has a primary offense of a ten inch spinning blade with hardened steel teeth.

- BeeF KaM takes a letter from each of our last names and gets his name from his beefy frame constructed using cam software.

DESIGN THOUGHTS:

- The frame of the robot was designed to be lightweight and strong, as it is composed of hollow aluminum square tube and thin polycarbonate plates.

- The drive system of two powered wheels and a free-sliding front is simple, yet effective.

- The high speed carbon steel toothed blade has a high potential to be very destructive against other small robots.

WHAT WAS LEARNED:

- The greatest hurdle of this project was that of constructing the frame. Being a slightly complex form that was welded together, it spent a very long amount of time in the weld shop setting us weeks behind schedule. We had to work together very quickly in order to make the final assembly of the robot.

- Aside from the frame, we all garnered much experience on manual and CNC machining operations as well as 3D printing to make all of the smaller components of the robot.

ROBOT NAME: FLIPPING AWESOME

TEAM MEMBERS: John Arts, Jenny James, Julian Rodriguez, Derik Waterman, Nicholas Walter

TEAM NAME: Team Awesome

CLASS: Evening

ROBOT FEATURES:

- Catapult

- Angled front attack

- Two sided drivability

- Aesthetically appealing

ROBOT DESIGN:

- We selected materials based on several factors. The material had to be readily available and cost effective. We chose material that was strong, yet light weight. The material also had to be easy to machine.

- We chose a wedge shape for our robot. The shape is strong and compliments our catapult weapon. It is also an easier shape to defend, and having a strong defense was as important to us as a strong offense.

WHAT WAS LEARNED:

- The members of our team come from 2 different programs: Mechanical Design and Process Engineering. We used skills from our different programs, as well as the personal knowledge of each of the members in the group. Our group got out of the gate fast with a design and got right to work machining and fabricating components.

- Our most challenging part of the construction was collaborating and coming up with a strategy to shed weight and keep our bot under 15 lbs.