Project Impact = Success!

What does it take to fix a leaky dog kennel? Seven Fond du Lac area ladies found out recently during Moraine Park Technical College’s Project Impact. The Humane Society of Fond du Lac had small, broken dog kennels with rotted and leaky drain troughs. These had become so bad that staff couldn’t use them for anything other than storing blankets and supplies. Four manufacturing programs at Moraine Park got together to show several area women how to plan, design, build, and install new troughs in this collaboration of community and instruction.

Moraine Park’s Project Impact was also recently featured on one of WBAY’s news broadcast, showcasing the work our instructor Larry Clark and the students put into the project.

Left to right: Devan Schrank (alumni), Kori Seigl (alumni), Genna Borths (student), Jennifer James (student), Nicole Corbin (Lincoln Electric), the lead “instructors” of Project Impact.

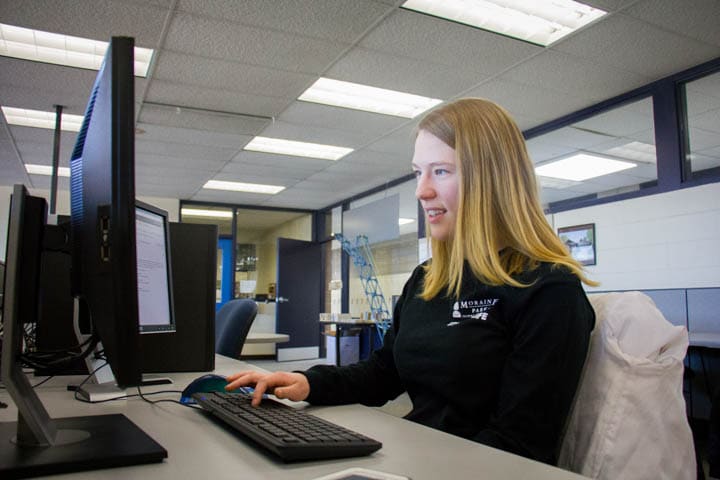

A team of five women led the instruction of Project Impact, including MPTC alumni Devan Schrank and Kori Siegl, current MPTC students Genna Borths and Jennifer James, and Nicole Corbin from Lincoln Electric (not affiliated with Moraine Park, but passionate about the project). Current MPTC faculty Larry Clark (Fabrication Technologies), Jeff Quackenboss (Mechanical Design) and Tom Roehl (Process Engineering) designed this event to give women experience designing and manufacturing a product as a community service.

How you ask? Participants learned how to use SolidWorks (3D CAD drafting software) and designed a solution to the current problem. They then used SigmaNest, a software used to take a SolidWorks plan and configure it to cut the pieces using a laser, to make new drains out of stainless steel donated by McNeilus Steel.

“I liked the feeling of accomplishment, we helped the Humane Society and we learned something new. We learned how to weld, and how to work with a press and stuff, so it was interesting.” -Tina Giese, Project Impact Participant

Once the new drains were cut, participants used a press brake to form the sides of the drain trough. Finally, the group welded the end caps and tubes to the troughs. This led to each woman learning a little bit about the manufacturing process including:

Metal Fabrication (Fabrication Technologies)

Once the troughs were manufactured, they needed to be installed. The old troughs were removed and the women then installed the new troughs in their place, connecting them to the drain system. This made 14 kennels that are unusable now and able to hold more dogs.

“This means we can now put the small dogs in the smaller cages. They get a little intimidated in the big cages next to the bigger dogs. That limited the amount of small dogs we could take in.” -Beth Rogan, Fond du Lac Humane Society

Replacing the drains would have cost about $10,000, but thanks to donations by McNeilus Steel, Lincoln Electric, and Moraine Park Technical College, and the time and effort of these seven Fond du Lac area women, the remodel cost the Humane Society nothing.

Genna Borths adds new trough to kennel.

MPTC Faculty Jeff Quackenboss gets locked in kennel

MPTC Alumni Kori Seigl showing off her caulking skills